VariMax25 NG is an alternative to VariMax CE.

The control unit is supplied in an enclosed format and must be combined with our

VariMax-motor25 NG. The VariMax NG series can be included as components in one of our drive sets.

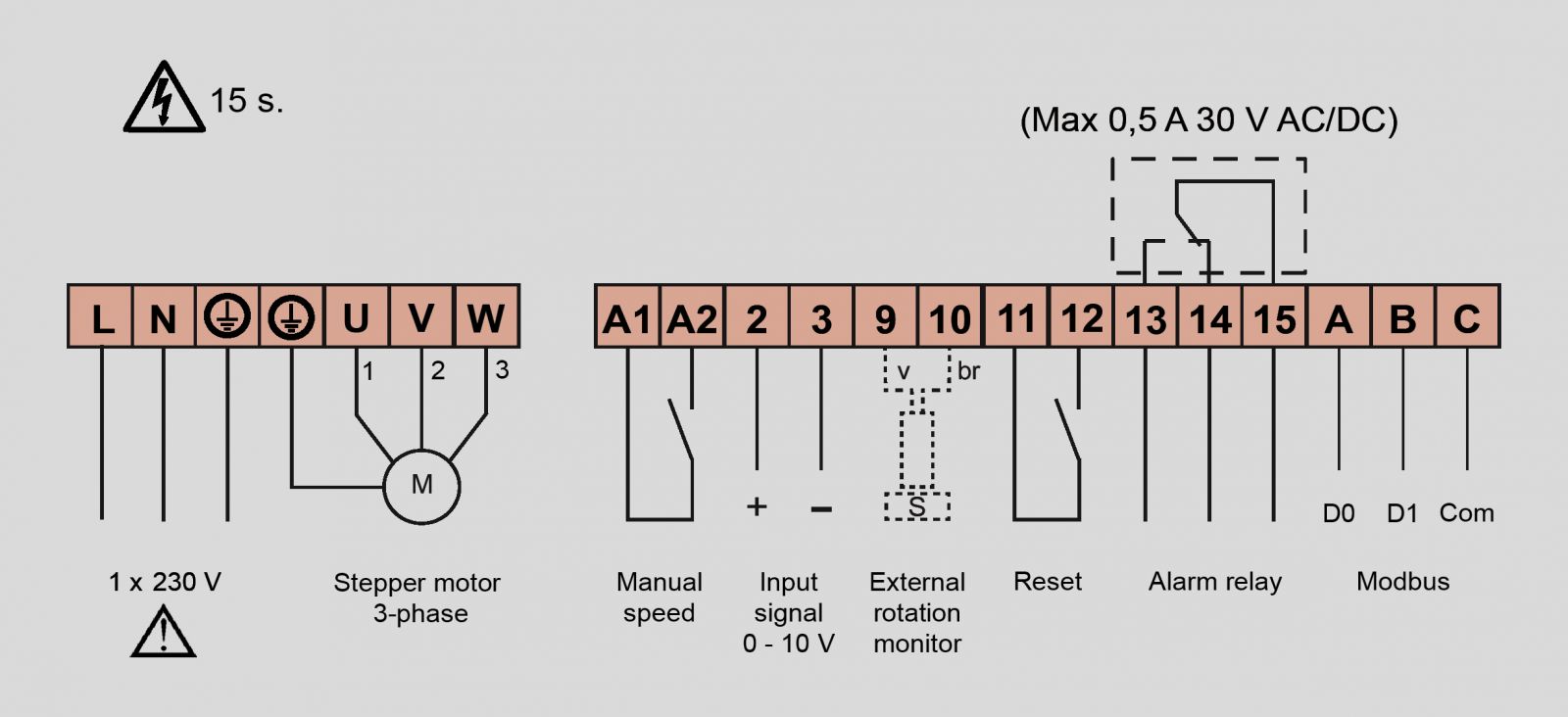

Connection diagram

Function description

The VariMax25 NG together with VariMax-motor25 NG constitutes a modern combination with specific additional functions for the optimal control of a rotating heat exchanger. The VariMax-motor25 NG is a stepping motor with substantial torque over the entire speed range. This means that the speed of a thermal rotor is between 0,1-12 rpm.

Input signal 0-10 V

The heat exchanger rpm is governed by the control unit so that the heat exchanger’s degree of efficiency is proportional to the input signal from the control centre.

Ceaning function

When the rotor has stopped for 10 minutes, the cleaning function is activated and the rotor starts to rotate. As a warning, the rotor first rotates for 6 seconds at a motor speed of 5 rpm, the rotor is then stationary for 3 seconds. After this, the actual cleaning starts, for a random time, between 10 to 20 seconds with the motor at 20 rpm.

Alarm

Rotation monitor

The VariMax25 NG has an internal rotation monitor. The rotation monitor is patent pending.

This is activated when the DIP switch for the “External rotation monitor” is in the OFF position.

The internal rotation monitor performs measurements at different times, depending on whether the speed of the motor is above or below 37 rpm.

At a motor speed above 37 rpm, the measurement begins when the speed is stable, normally starting after about 30 seconds, after which measurements are carried out continually. The yellow “Rotation” LED flashes after each completed, approved measurement. The time between the measurements varies from 22 seconds to nearly two minutes.

At a motor speed below 37 rpm, the control unit will increase the speed to 37 rpm at two-hour intervals. At start-up, this measurement will start after 10 minutes. The speed will remain steady for 2 minutes, while the actual measurement is being performed. To verify the measurement, an additional measurement is conducted 10 minutes later. If both of these measurements are positive, i.e. everything is normal, the next measurement will not take place until two hours later.

This sequence is then repeated with the same time intervals, provided the motor speed is below 37 rpm.

As an alternative, the VariMax25 NG can have an external rotation monitor (magnet mounted on the rotor with an associated rotation monitor). This is connected at terminal connections 9 and 10, and the DIP switch for the “External rotation monitor” should be in the ON position.

External faults

The control unit trips and generates an alarm in the event of

Over/undervoltage

Over/under temperature

Motor fault

Short circuit phase-phase or phase-earth.

Internal fault

Alarms and trips if an internal fault occurs in the control unit.

All alarms are remaining

Manual speed

Possibility of externally controlling the speed.

The speed is adjusted with a separate potentiometer.

Test

DIP switch for manual run at high or low speed rpm.