MicroMax1500 is intended for rotors up to 8000 mm with a rotor speed of max 12 rpm. If the wheel requires a faster wheel speed

(12-25 rpm), the wheel diameter should be reduced. Standard delivery includes an enclosed control unit, but can be supplied in a customised format. All control units in the MicroMax series can be included as components in one of our popular Drive sets.

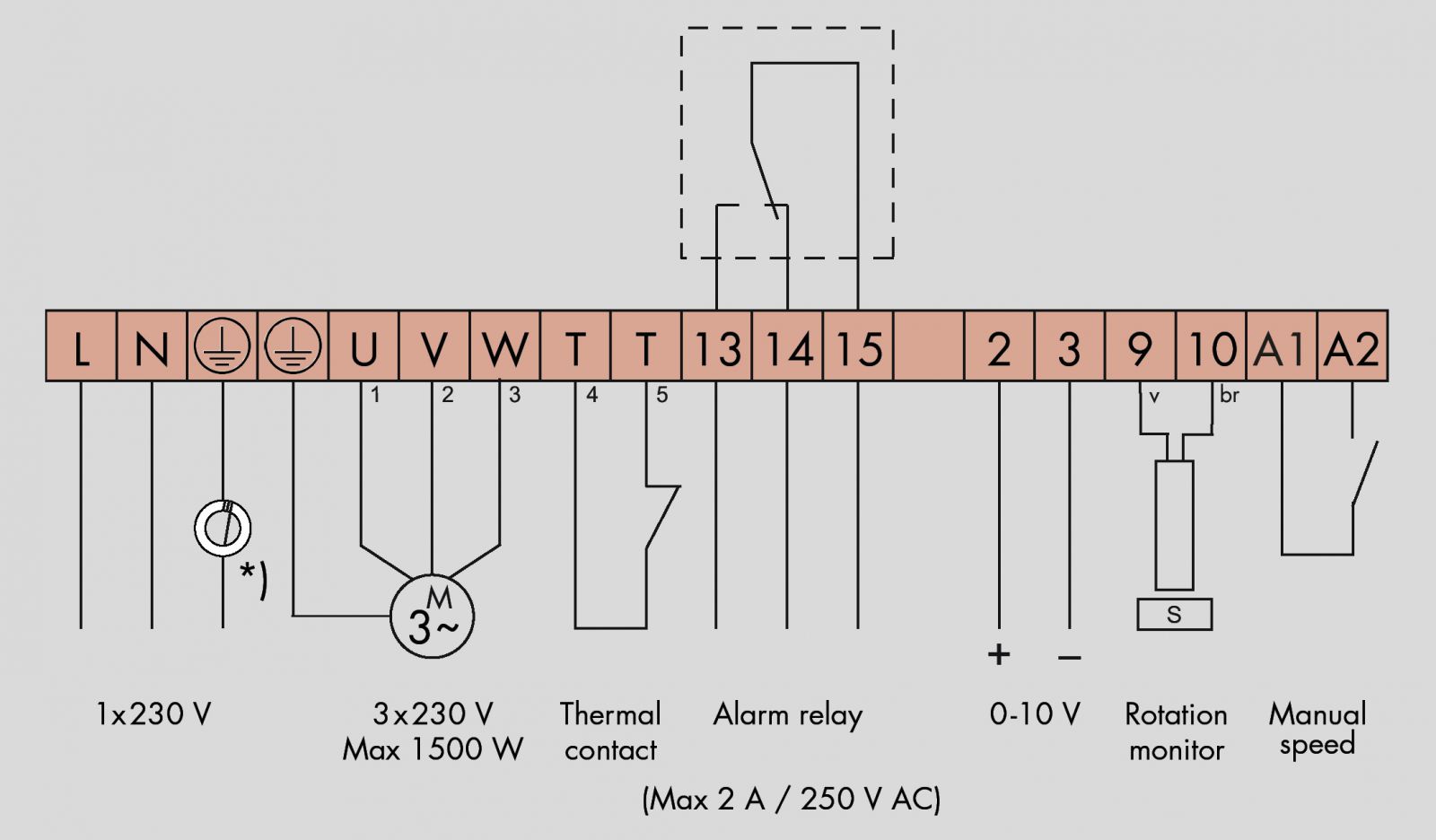

Control diagram

*) To achieve EMC Class C3, the supplied ferrite has to be installed on the incoming earth wire. The earth wire has to be approximately 15 cm longer than the other wires and shall be wrapped around the ferrite three times before being connected to the terminal.

Function description

The MicroMax product series consists of modern control units with specific additional functions for the optimal control of a rotating heat exchanger.

Input signal 0-10 V

Heat exchanger rpm and thus thermal efficiency are governed by the control unit so that wheel speed is proportional to the input signal from the control centre. If the input signal is less than the set threshold value the rotor is stopped.

Cleaning function

When the wheel has stopped for 30 minutes, the cleaning function is activated and the wheel rotates at minimum rpm for 10 seconds.

Rotation monitor

The rotation monitor stops the control unit and generates an alarm if the rotor stops rotating. The control unit generates an alarm and trips unless a pulse is received every 5 minutes. The alarm event is retained.

Alarm

The control unit trips and generates an alarm in the event of over or under-voltage,

short-circuiting or earth leakage, and if a thermal switch has tripped inside the motor. All alarm events are retained.

Manual speed

Possibility of externally controlling the maximum speed.

Test

DIP switch for manual run at high or low speed rpm.